Keine Artikel

Geschäftsführung

Katalog

Dipl. Ing. Dr. techn. Oskar Kehrer

Mehr als 30 Jahre praktische Erfahrungen in der Industrie als Executive Manager, Yield Manager, Production Manager, Manager Industrial Engineering, Manager Process Engineering, European Welding Engineer, International Welding Engineer,...

Dipl. Ing. Dr. techn. Oskar Kehrer

Mehr als 30 Jahre praktische Erfahrungen in der Industrie als Executive Manager, Yield Manager, Production Manager, Manager Industrial Engineering, Manager Process Engineering, European Welding Engineer, International Welding Engineer, Works Inspector und Schweißaufsicht Aerospace Technology.

Steyr-Daimler-Puch Fahrzeugtechnik, Magna Steyr, Magna Powertrain, Kendrion Electromagnetics - eh. Binder Magnete,

TDK / EPCOS / Siemens. Nebenberuflich viele Jahre als Berater / Trainer / Coach für Merten Management International.

zusätzliche Qualifikationen (Auswahl):

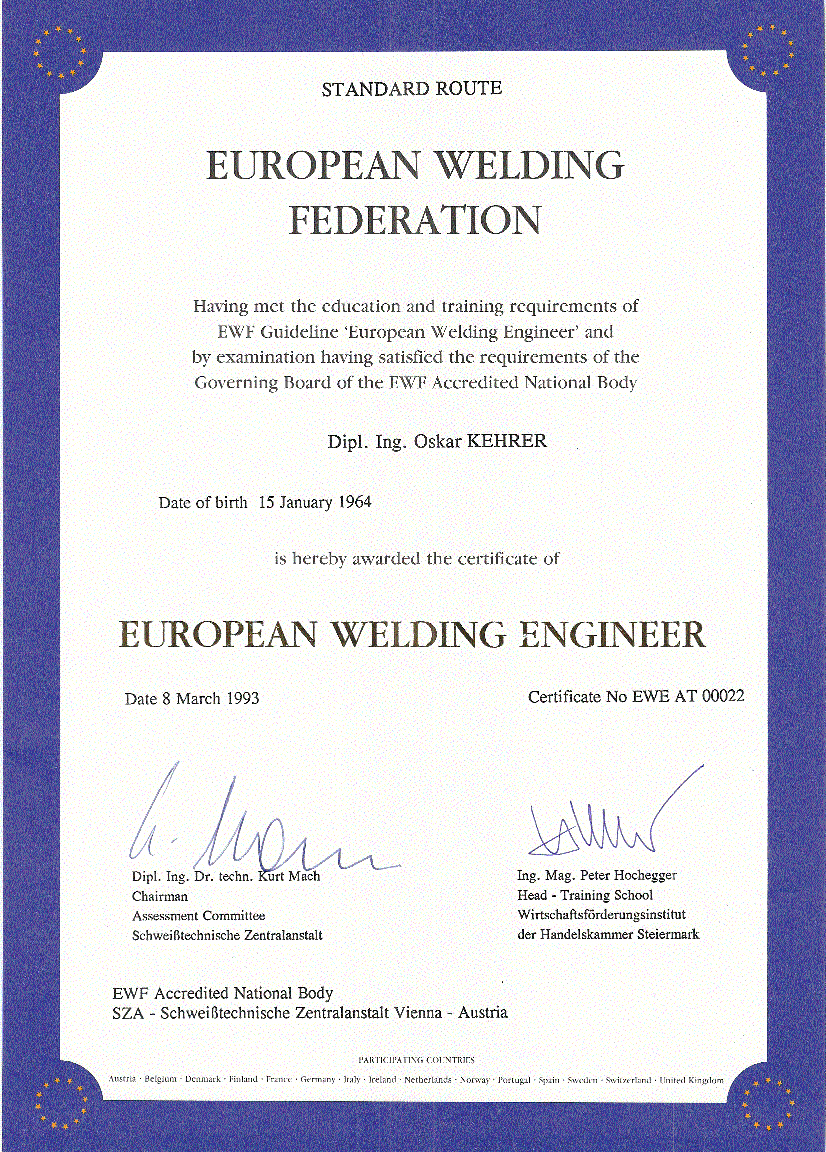

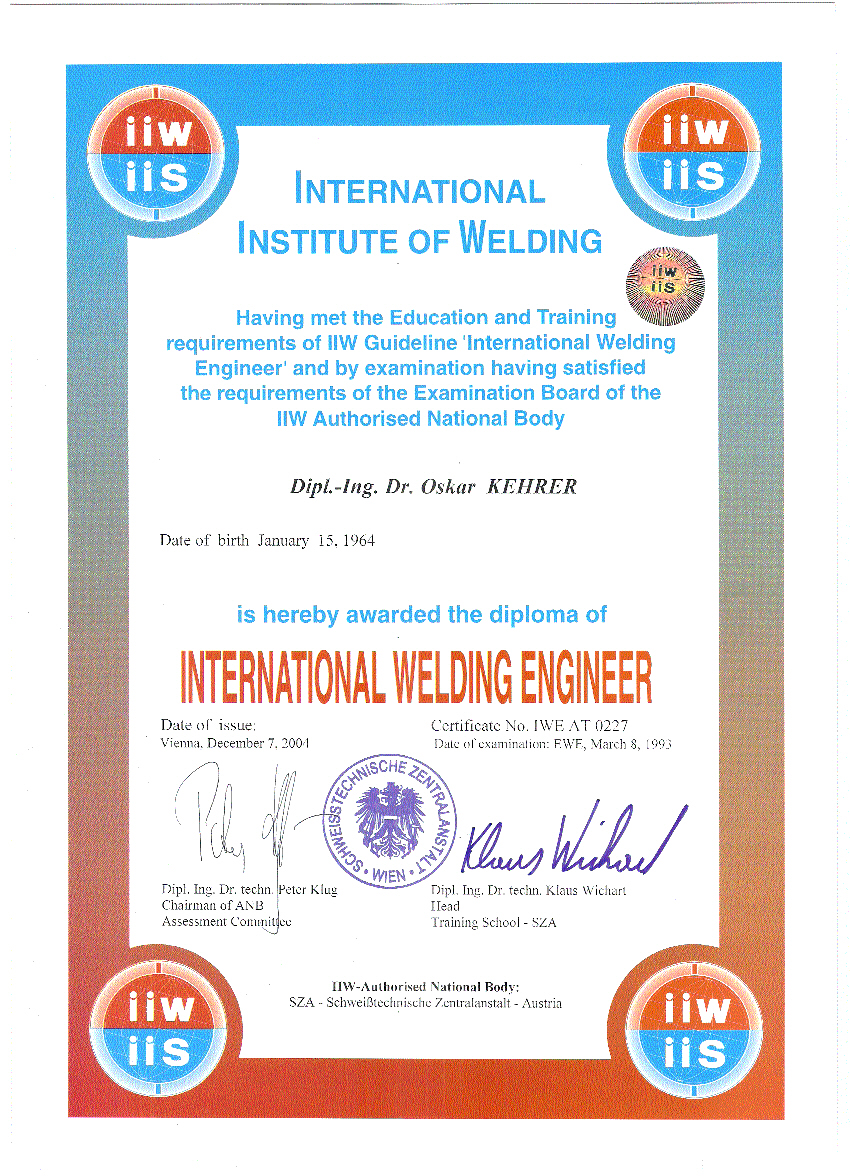

European Welding Engineer (EWE), International Welding Engineer (IWE), Six Sigma Champion, Führen, Projektmanagement, Wertanalyse, Design of Experiments (DoE), FMEA, REFA (Arbeitswissenschaft)

Schulbildung:

HTL Bulme Graz: Betriebstechnik

TU Graz: (Dipl. Ing.) Wirtschaftsingenieurwesen Maschinenbau / Spezialisierung: Mikroprozessoren und technische Datenverarbeitung

TU Wien: (Dr. techn.) Maschinenbau. Spezialgebiete: Qualitätsmanagement, Fertigungstechnik, Physik.

Dissertation (Institut für Hochleistungsstrahltechnik): Einfluss und Optimierung von Schweiß- und Prozessparametern hinsichtlich Schweißnahtqualität mit Hilfe von Design of Experiments bei CO2-Hochleistungslasern

Erfinder aus den Bereichen Schweißtechnik, Werkstofftechnik, Laser, Wärmebehandlung, Härterei, Oberflächen-Beschichtungen, Fahrzeugtechnik, Maschinenbau, Elektronik, Messtechnik, Sensorik, MultilayerTechnologie verwendet bei MLCC (keramische Kondensatoren), Piezo Stacks (Diesel- und Benzineinspritzsysteme wie Pumpe/Düse oder CommonRail), Piezo Aktuatoren, MLV (Varistoren), NTC (Temperatursensoren).

Patentanmeldungen, die in Produkten oder Prozessen der industriellen Serienfertigung in hoher Stückzahl benützt werden:

- CN103430641(A) - 2013-12-04; Method for producing a film stack, and equipment for producing a film stack

- EP 2689645 (A1) - 2014-01-29; METHOD FOR PRODUCING A FILM STACK, AND SYSTEM FOR PRODUCING A FILM STACK

- WO2012126787 - 2012-09-27; METHOD FOR PRODUCING A FILM STACK, AND SYSTEM FOR PRODUCING A FILM STACK

- DE102011014583 - 2012-09-27; Verfahren zur Herstellung eines Folienstapels und Anlage zur Herstellung eines Folienstapels

- US2007029290 - 2007-02-08; Method for the plasma, laser or electron beam welding of identical or different materials with a tendency for excessive hardening, with copper or a copper alloy as a filler material

- EP1667810 (A1) 2006-06-14; Method for the plasma, laser or electron beam welding of identical or different materials with a tendency for excessive hardening, with copper or a copper alloy as a filler material

- AT7047 (U1) - 2004-09-27 VERFAHREN ZUM SCHWEISSEN

- JP2007508145 - 2007-04-05 VERFAHREN ZUM SCHWEISSEN

- CA2541236 (A1) - 2005-04-07 METHOD FOR THE PLASMA, LASER OR ELECTRON BEAM WELDING OF IDENTICAL OR DIFFERENT MATERIALS WITH A TENDENCY FOR EXCESSIVE HARDENING, WITH COPPER OR A COPPER ALLOY AS A FILLER MATERIAL

- WO2005030423 (A1) - 2005-04-07 METHOD FOR THE PLASMA, LASER OR ELECTRON BEAM WELDING OF IDENTICAL OR DIFFERENT MATERIALS WITH A TENDENCY FOR EXCESSIVE HARDENING, WITH COPPER OR A COPPER ALLOY AS A FILLER MATERIAL

- EP1681365 (A1) - 2006-07-19; Method of producing highly stressed machine components

- AT8065 (U1) - 2006-01-15; STAHL FÜR EINSATZGEHÄRTETE HOCHBEANSPRUCHBARE MASCHINENTEILE

- EP1566454 (A1) - 2005-08-24; Process for producing nodular cast iron products and products obtained

- US2004219052 (A1) - 2004-11-04; High-strength, high-ductility noudlar iron, and transmission housing produced therefrom

- WO03014407 (A1) - 2003-02-20; HIGH-STRENGTH, HIGH-DUCTILITY NODULAR IRON, AND TRANSMISSION HOUSING PRODUCED THEREFROM

- JP2004537652 (A) - 2004-12-16; HIGH-STRENGTH, HIGH-DUCTILITY NODULAR IRON, AND TRANSMISSION HOUSING PRODUCED THEREFROM

- EP1415009 (B1) - 2006-01-25; HIGH-STRENGTH, HIGH-DUCTILITY NODULAR IRON, AND TRANSMISSION HOUSING PRODUCED THEREFROM

- EP1415009 (A1) - 2004-05-06;

- CA2456432 (A1) - 2003-02-20; HIGH-STRENGTH, HIGH-DUCTILITY NODULAR IRON, AND TRANSMISSIONHOUSING PRODUCED THEREFROM

- AT5381 (U1) - 2002-06-25; HIGH-STRENGTH, HIGH-DUCTILITY NODULAR IRON, AND TRANSMISSION HOUSING PRODUCED THEREFROM

- US2004136776 (A1) - 2004-07-15; Shaft comprising a part connected thereto by welding Link: High-Beam-Research

- US7137897 (B2) - 2006-11-21; Shaft comprising a part connected thereto by welding

- WO02070911 (A1) - 2002-09-12; EP1368573 (A1) - 2003-12-10; SHAFT COMPRISING A PART CONNECTED THERETO BY WELDING

- JP2004522913 (A) - 2004-07-29; SHAFT COMPRISING A PART CONNECTED THERETO BY WELDING

- CA2440084 (A1) - 2002-09-12; SHAFT COMPRISING A PART CONNECTED THERETO BY WELDING

- AT5144 (U1) - 2002-03-25; SHAFT COMPRISING A PART CONNECTED THERETO BY WELDING

- AT7409 (U1) - 2005-03-25; VERFAHREN ZUR HERSTELLUNG EINES WERKSTÜCKES AUS SPHÄROGUSS UND NACH DIESEM HERGESTELLTES WERKSTÜCK

- DE10241947 (A1) - 2003-04-03; Process for surface treating a weakly loaded machine element comprises mechanically working the workpiece and coating the contact zones with a nickel layer having embedded particles of an oscillating damping non-metal

- AT316586 (T) - 2006-02-15; SPHAROGUSS MIT HOHER FESTIGKEIT UND DUKTILITAT UND DARAUS HERGESTELLTES GETRIEBEGEHAUSE

- US6589671 (B1) - 2003-07-08; Method for joining a cast part and a case-hardened steel part and component manufactured according to said method

- WO9958287 (A1) - 1999-11-18; METHOD FOR JOINING A CAST PART AND A CASE-HARDENED STEEL PART AND COMPONENT MANUFACTURED ACCORDING TO SAID METHOD

- JP2002514511 (A) - 2002-05-21; METHOD FOR JOINING A CAST PART AND A CASE-HARDENED STEEL PART AND COMPONENT MANUFACTURED ACCORDING TO SAID METHOD

- EP1087855 (A1) - 2001-04-04; METHOD FOR JOINING A CAST PART AND A CASE-HARDENED STEEL PART AND COMPONENT OBTAINABLE BY SAID METHOD

- EP1087855 (B1) - Link 2003-01-29; METHOD FOR JOINING A CAST PART AND A CASE-HARDENED STEEL PART AND COMPONENT OBTAINABLE BY SAID METHOD (Verfahren zum Verbinden eines Gussteiles mit einem Teil aus einsatzgehärtetem Stahl und Bauteil erhältlich durch dieses Verfahren)

Auszug von persönlichen Zertifizierungen: